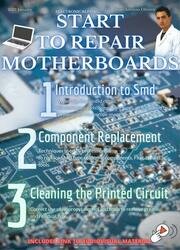

Название: Start Repairing Laptop and Cell Phone Motherboards Today on Basic Fast Course: Basic guide to start learning and repairing motherboards in the process of quick repair Название: Start Repairing Laptop and Cell Phone Motherboards Today on Basic Fast Course: Basic guide to start learning and repairing motherboards in the process of quick repair

Автор: Juan Olivera

Издательство: Amazon.com Services LLC

Год: 2021

Язык: английский

Формат: pdf

Размер: 10.7 MB

Surface mount technology is the most widely used electronic device construction method today.

In electronics, a printed circuit board is a surface made up of paths, tracks or buses of conductive material laminated on a non-conductive base. In short, to streamline learning; the printed circuit forms the board where the components will be mounted.

Tin is a chemical element.

It melts at a low temperature; it has great fluidity when melted and has a high boiling point.

Solder tin is not pure tin, but an alloy, usually tin and lead.

The ideal composition is 60% tin to 40% lead with the addition of flucs resin to facilitate tinning but, in the traditional composition used by electronic components to be mounted on the printed circuit, this tin does not contain the alloy with lead for polluting reasons and it is for this reason that in the type of contact solder with tin balls

(BGA solder) it does not have the consistency that lead alloy generates, and the solder deforms more easily.

The tools needed to remove and weld surface mount components are:

Hot air station, tin soldering iron with ceramic resistance, flux liquid flux, anti static tweezers, tin wire.

If there are also more tools, the fundamental ones are those mentioned above.

We now begin the extraction process.

We select the component that we want to extract and add liquid flux on it, place the nozzle of our hot air gun 1 centimeter from the component, and proceed with the help of the tweezer to circle around the component until we see that the tin has reached its boiling point, and we proceed to the extraction of the surface mount chip.

Скачать Start Repairing Laptop and Cell Phone Motherboards Today on Basic Fast Course: Basic guide to start learning and repairing

|