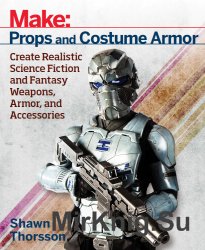

Название: Make: Props and Costume Armor: Create Realistic Science Fiction & Fantasy Weapons, Armor, and Accessories

Издательство: Maker Media, Inc

Автор:Shawn Thorsson

Год: 2016

Количество страниц:288

Язык: English

Формат: pdf

Размер:42 Mb

Prop making represents the ultimate collision of creative imagination and practical maker skills. Sculpting, molding, casting, 3D printing, CNC fabrication, wood- and metalworking, and painting are among the many techniques the seasoned prop maker employs. In this book, master prop maker Shawn Thorsson reveals the tools, techniques, and processes that you can use to create professional-looking science fiction and fantasy props and armor. In this book, you'll learn:

how to use the popular Pepakura software to build 3D models with paper

a variety of molding and casting techniques

how to build a "vacuforming" machine to make armor from plastic sheet stock

painting and weathering techniques that will bring your props to life

Preface v

Acknowledgements xiii

Part I Prototypes and One-Offs

�� Building with Sheets and Tubes 3

Starting Off Easy

Starting Off Simple 4

Battle Axe for the Wolf Warrior 8

Hunter’s Rifle 18

�� Working with Pepakura 29

Print a Science Fiction Helmet on

Your Inkjet

Pepakura Boot Camp 30

Putting Pepakura to�Work 35

Making It Hard 43

Making It Smooth 50

Detailing 53

�� EVA Foam 57

Turning Floor Mats into Armor

Sourcing: Where to Get�Foam 58

The Basics: Making Foam Obey Your

Every�Whim 59

Patterning 64

Final Detailing 77

Prepping for Paint 79

Paint! 80

�� 3D Printing and CNC Carving 81

Let the Robots Do the Work

Part II Molding and Casting

�� Mold-Making Basics 87

Leave a Lasting Impression

The Simplest Molds Ever 88

Mold-Making Material 88

Mold-Making Terminology 89

�� One-Piece Molds 93

You’ve Got to Start Somewhere

Easy Version: A Part with a Flat Backside 93

Slightly Harder Version: A Piece with

Details on All Sides 101

�� Multi-Piece Molds 109

When You Need to See Both Sides

Starting Simple: A Two-Part Mold

with a Mold Box 110

Not So Simple: A Three-Piece Silicone

Rubber Jacket Mold with a

Mother Mold 117

A Few Tips and Tricks for Better Castings 131

�� Molds for Rotocasting 133

Bigger Doesn’t Have to Cost More

Prepare the Prototype 135

Prepare the Work Space 136

Building Up the Rubber�Jacket 136

Building the Mother�Mold 140

Rotocasting 147

Trimming and Prepping the Cast

Part for Painting 150

Part III Vacuum Forming

�� Vacforming Basics 155

Make Factory-Looking Parts at Home

Terminology 156

Designing the Forming�Bucks 156

Building the Forming Bucks 157

Choosing Plastics for Vacforming 163

The Simplest Possible Vacforming Setup 164

��� Build Your Own Vacuum

Forming Machine 175

Step Up Your Game by Stepping Out

of the Kitchen

Begin by Building the Clamping Frame 176

Heat Sources 179

Common Configurations 180

Building the Platen 183

Vacuum Sources 184

Putting It to Work 188

Part IV Painting and Weathering

��� Basecoats and Masking 193

Building a Believable Finish Starts with a

Solid Foundation

More Than You Ever Wanted to Know

About Paint 194

Basecoats: Building a Believable Finish

Starts with a Solid Foundation 196

Masking and Stenciling 205

��� Faux Finishes 209

Making Something into Something Else

Metal 210

Leather 212

Wood Grain 214

Carbon Fiber 218

��� Weathering 221

The Fastest Way to Wear and Tear

Additive Weathering 222

Subtractive Weathering 227

Mud 230

Rust 231

The Path to Patina 236

Scorches and Burn Marks 237

Burnt Metal 238

Blood Spatter 239

Part V Bringing it All Together

��� Strapping and Padding 245

Hold Yourself Together!

Padding 246

Armor Attachment Options 247

Strapping Materials 249

Buckles and Related Hardware 249

How to Attach Straps to�Stuff 250

Design Considerations for Strapping

Your Armor Together 253

The Tricky Bits 254

Odds and Ends: A Few More

Strapping Tips 260

��� Showing Off 263

Now That You've Got It, Flaunt It!

Handlers 263

Field Repair Kit 264

Posing for Photos 265

Planned Photoshoots 266

Index 269

depositfiles.com

turbobit.net

|